What Is an Actuator?

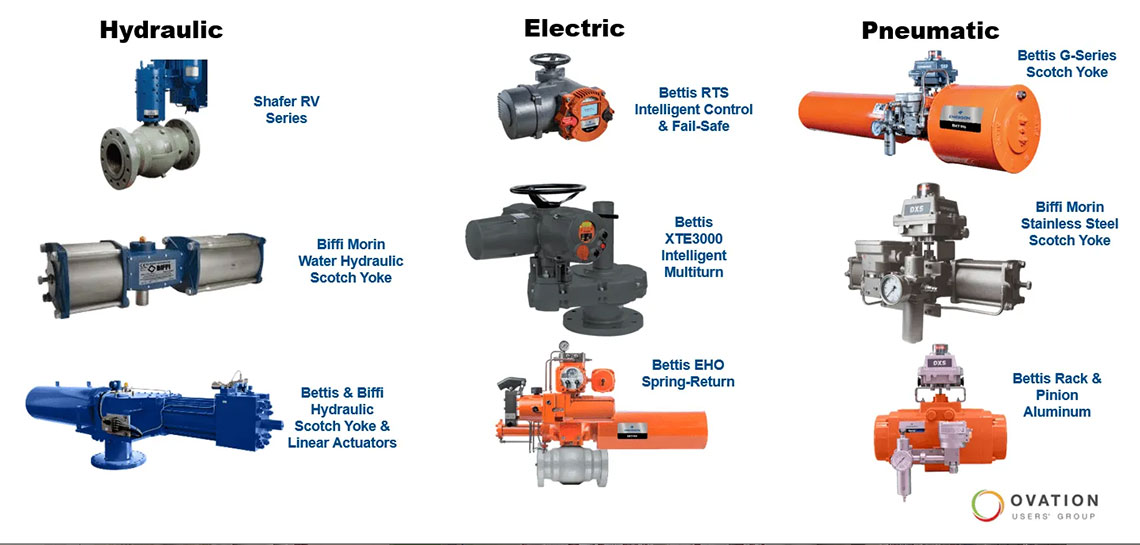

An actuator is a device that moves or controls a mechanism or system. It receives a control signal and responds by converting that energy into motion. Depending on the source of power and application, actuators can be classified into several types: electric, pneumatic, hydraulic, mechanical, and thermal.

Electric Actuators

Industrial Applications:

- Valve automation in water treatment facilities

- Conveyor systems in material handling

- Robotics in assembly lines

Pneumatic Actuators

Industrial Applications:

- Automated door systems

- Process control valves in the food and beverage industries

- High-speed packaging equipment

Hydraulic Actuators

Industrial Applications:

- Heavy machinery in mining

- Lifting mechanisms in construction

- Press operations in manufacturing

Mechanical Actuators

Mechanical actuators rely on gears, levers, or screws to translate motion. While not as common as other types, they remain useful in specific low-tech or backup applications.

Industrial Applications:

- Manual override systems

- Basic positioning devices

- Emergency shutoff mechanisms

Their simplicity and reliability make mechanical actuators ideal in scenarios where power sources are unavailable, or automation is not feasible.

Thermal Actuators

Thermal actuators use temperature changes to drive movement. When heated, they expand or trigger a material to change shape, initiating mechanical motion.

Industrial Applications:

- HVAC systems

- Temperature-sensitive safety devices

- Small-scale laboratory automation

These actuators provide slow, controlled motion and are suitable for temperature-triggered responses.

Key Factors to Consider When Selecting an Actuator

Choosing the right actuator depends on several factors:

- Load requirements: How much force or torque is needed?

- Speed and precision: Does the application demand quick or controlled movement?

- Operating environment: Will the actuator be exposed to moisture, chemicals, or extreme temperatures?

- Control systems: Does it need to integrate with PLCs or remote monitoring systems?

- Maintenance: What are the costs and complexity of upkeep?

Maintenance Best Practices for Long-Term Actuator Performance

Routine maintenance is essential to ensure actuators remain responsive and accurate over time. This includes regularly inspecting seals and lubricants, checking for wear or misalignment, and verifying electrical or pneumatic connections. For actuators in mission-critical operations, implementing a predictive maintenance schedule based on real-time performance data can prevent unexpected failures.

It’s also crucial to calibrate actuators periodically to maintain precision in valve positioning or system control. Choosing actuators with built-in diagnostics can simplify this process and help teams detect issues early, extending service life and reducing total cost of ownership.

Emerging Trends in Actuator Technology

Modern actuators are evolving to meet the needs of smart manufacturing. Some notable innovations include:

- Smart actuators with built-in sensors for real-time diagnostics

- Wireless communication for remote adjustments

- Energy-efficient designs for sustainability

How to Match Actuators to Environmental Conditions

When selecting actuators for industrial environments, the operating conditions must be a key consideration. Factors such as temperature extremes, humidity, corrosive chemicals, dust, and explosive atmospheres can directly impact actuator longevity and reliability. For instance, actuators in offshore oil and gas operations must be resistant to saltwater corrosion and function reliably in harsh marine conditions. In food and beverage plants, hygienic design and easy cleanability are critical. Matching actuator materials, sealing, and enclosures to these specific environmental requirements ensures optimal performance, reduces maintenance, and helps avoid premature failures that could disrupt operations or compromise safety.

Proconex Actuator Solutions

Our actuator offerings are designed to support critical operations across a range of industries, including oil and gas, chemical processing, water treatment, and manufacturing. With in-house expertise and local service capabilities, we provide more than just products: we offer long-term solutions that improve performance and reliability.

In Conclusion

Ready to upgrade your automation infrastructure? Explore our actuator solutions today.