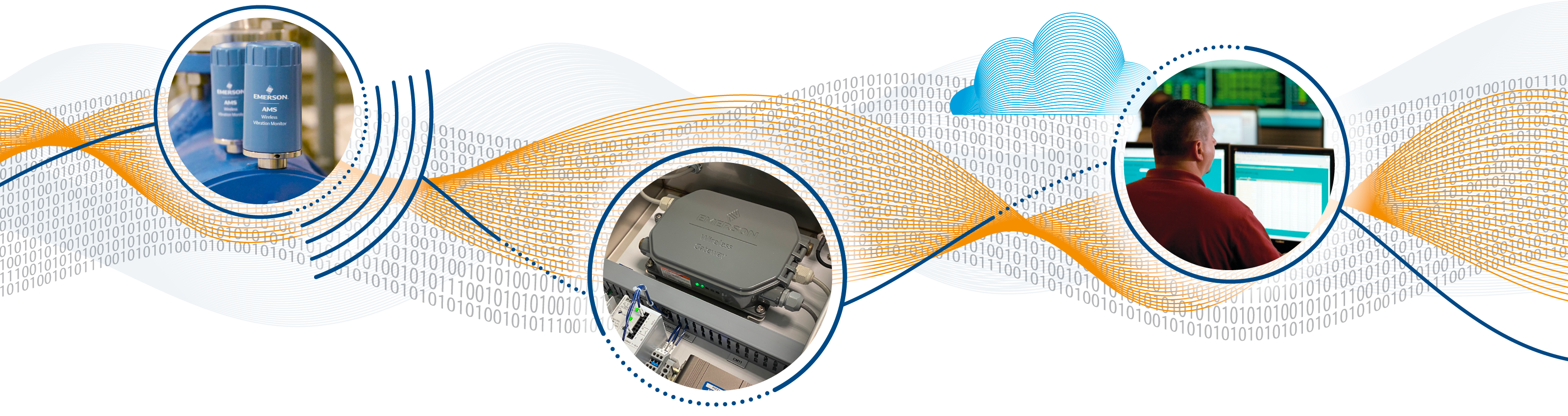

Install AMS Wireless Vibration Monitors

Gain a complete view of your asset health, including overall values and analysis of parameter trends.

Extend your reliability program to an unprecedented number of plant assets including those in hazardous or hard to reach areas.

Connect with host systems and data applications—via WirelessHART® networks—to ensure that field devices have the most reliable path to send data.

Extend your reliability program to an unprecedented number of plant assets including those in hazardous or hard to reach areas.

Connect with host systems and data applications—via WirelessHART® networks—to ensure that field devices have the most reliable path to send data.