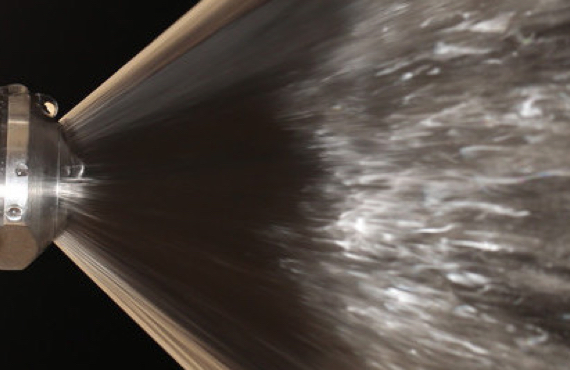

Improper Spray Water Nozzle Maintenance Can Lead to:

- Poor quality steam

- Erosion and wear on piping

- Damage to downstream equipment

- Decreased capacity leading to underspray

- Lost production efficiency and revenue

- Inadequate temperature control

Ignoring these warning signs can further lead to stretched tubes or tube failures, cracked elbows, thermal liner cracking, or cracked welds.