Why Choose Proconex for Failure Analysis?

When machinery fails, you need more than just a quick fix—you need actionable insights that prevent future issues. At Proconex, our RCFA services go beyond standard troubleshooting to deliver long-term reliability and measurable results.

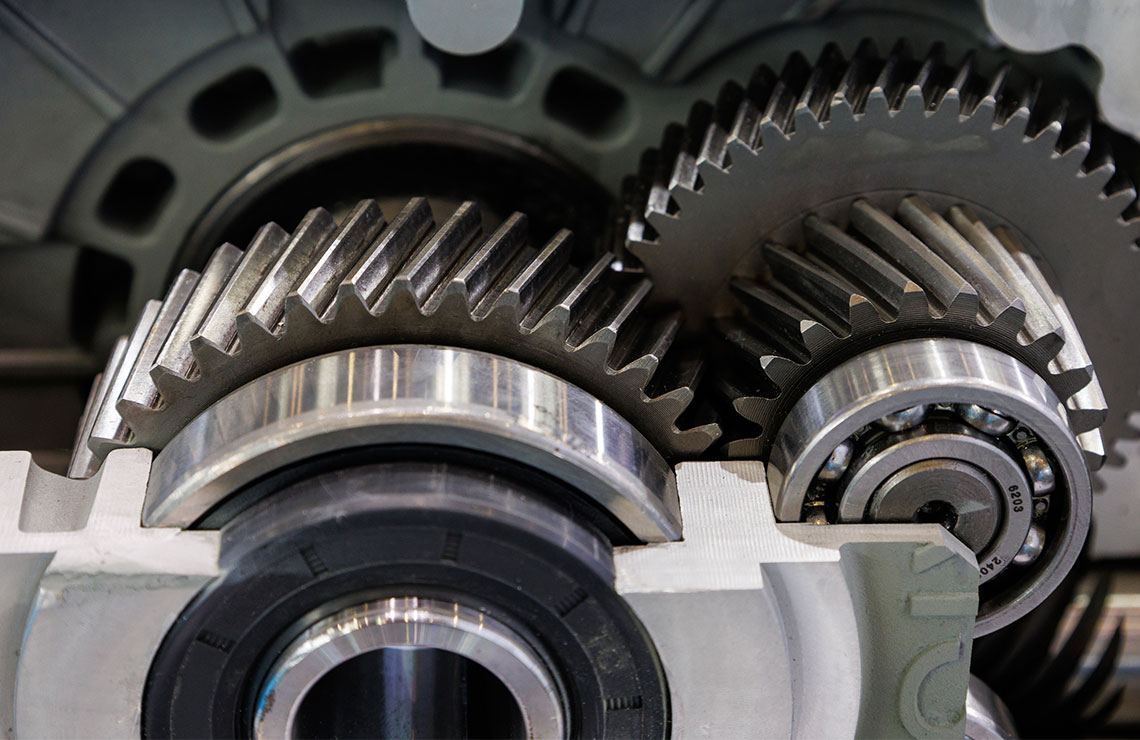

Expertise in Equipment Failure Analysis

Our engineers bring decades of experience in equipment failure analysis across industrial and manufacturing environments.

Proven Methodologies

We apply trusted, industry-recognized standards such as SAE-JA1011, Failure Mode and Effects Analysis (FMEA), and Reliability Centered Maintenance (RCM). These structured approaches ensure every investigation meets the highest engineering and reliability benchmarks.

Data-Driven Insights for Sustainable Improvement

Each failure analysis delivers clear, data-backed recommendations tailored to your operation. Our reports help you strengthen maintenance programs, improve asset reliability, and reduce costly unplanned downtime.

Collaborative Approach

We work closely with your team to ensure findings are understood and corrective actions are practical, achievable, and aligned with your operational goals.