This blog post explains how modern steam solutions improve performance, why steam quality matters more than most teams realize, and what plant leaders can do today to get more value from their steam systems without costly overhauls.

Why Steam Still Matters in Industrial Operations

Steam remains essential because it delivers energy that is clean, controllable, and incredibly versatile. Manufacturing plants rely on steam for heating, sterilization, humidification, power generation, and chemical processing. Food and beverage facilities depend on steam for cooking, sanitation, and pasteurization. Pharmaceutical and life sciences operations use steam where precision and purity are nonnegotiable.

What makes steam so valuable is its ability to transfer large amounts of energy efficiently. One pound of steam can release a tremendous amount of latent heat as it condenses. That characteristic allows steam systems to deliver consistent process energy with minimal footprint.

The challenge is not steam itself. The challenge is how steam is generated, managed, and controlled once it enters the system.

Understanding Steam System Efficiency

Steam system efficiency refers to how effectively a facility converts fuel into usable steam energy and how well that energy reaches the process load. Losses typically occur at four points:

- Steam generation at the boiler

- Distribution through piping and valves

- Control at the point of use

- Condensate recovery and return

Even small inefficiencies compound quickly. A leaking valve, failed steam trap, or poorly controlled pressure drop can waste thousands of dollars per year in fuel and maintenance costs.

Improving efficiency does not always require replacing boilers or redesigning infrastructure. In many cases, targeted steam solutions deliver meaningful gains with limited disruption.

The Role of Steam Management Systems

Effective steam management helps plants:

- Maintain consistent process conditions

- Reduce energy waste and unplanned downtime

- Protect equipment from water hammer and erosion

- Improve overall system reliability

Why Steam Quality Is Critical

There are four primary effects of steam quality on industrial operations:

- Heat Transfer Efficiency - Wet or contaminated steam delivers less usable energy. Processes take longer to reach temperature, increasing cycle times and fuel consumption.

- Equipment Longevity - Water droplets and contaminants accelerate erosion in valves, control devices, and piping. Over time, this leads to leaks, failures, and costly repairs.

- Process Consistency - Inconsistent steam quality causes temperature fluctuations that impact product quality, especially in food, chemical, and pharmaceutical applications.

- Safety and Reliability - Poor steam quality increases the risk of water hammer, which can damage equipment and create serious safety hazards.

Key Components of Effective Steam Solutions

Reliable steam systems depend on a combination of well selected components working together. The most impactful areas include:

Steam Control Valves

Control valves regulate pressure and flow to match process demand. Proper sizing and selection are critical. An oversized valve leads to poor control and accelerated wear. An undersized valve restricts flow and limits system capacity.

High quality steam control valves provide stable operation across varying loads and help prevent excessive pressure drops.

Steam Traps and Condensate Management

Steam traps remove condensate without allowing live steam to escape. Failed or poorly maintained traps are one of the most common sources of energy loss in steam systems.

A robust condensate management strategy improves efficiency, protects equipment, and supports sustainability goals by returning hot condensate to the boiler.

Pressure Reducing and Conditioning Stations

Many processes require steam at lower pressures than the main header. Pressure reducing stations ensure steam is delivered at the correct pressure and temperature while maintaining stability and safety.

Well designed stations reduce wear on downstream equipment and improve process control.

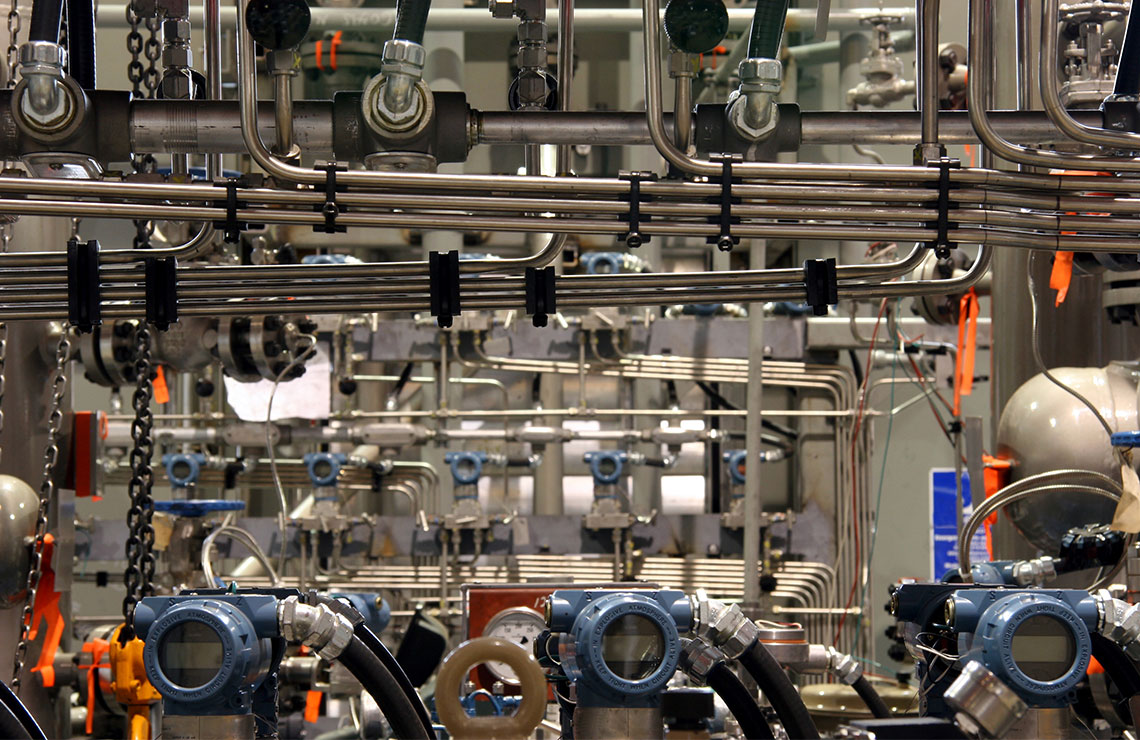

Measurement Instrumentation

Measurement instrumentation systems provide insight into how the steam system actually performs. Pressure, temperature, and flow data help teams identify inefficiencies, diagnose issues, and validate improvements.

Even basic monitoring can reveal problems that would otherwise remain hidden.

How to Calculate and Improve Steam Efficiency

- Insulate exposed steam and condensate piping

- Repair leaks and replace failed steam traps

- Verify control valve sizing and operation

- Ensure condensate is effectively returned to the boiler

- Match steam pressure to actual process requirements

Partnering for Smarter Steam Systems

Proconex offers a comprehensive range of steam solutions designed to improve efficiency, reliability, and control across industrial environments. From valves and control devices to complete steam management strategies, the focus is on practical results that support long term performance.

To explore options that fit your operation, Discover Our Steam Solutions and see how smarter steam management can drive measurable improvements across your facility.