For plant managers, reliability engineers, and operations leaders, rotating equipment services are a critical layer of plant safety. Proper inspection, monitoring, and servicing of rotating machinery reduce the risks associated with moving components and help ensure safe, predictable operation across the facility.

Rotating Equipment Is Central to Plant Safety

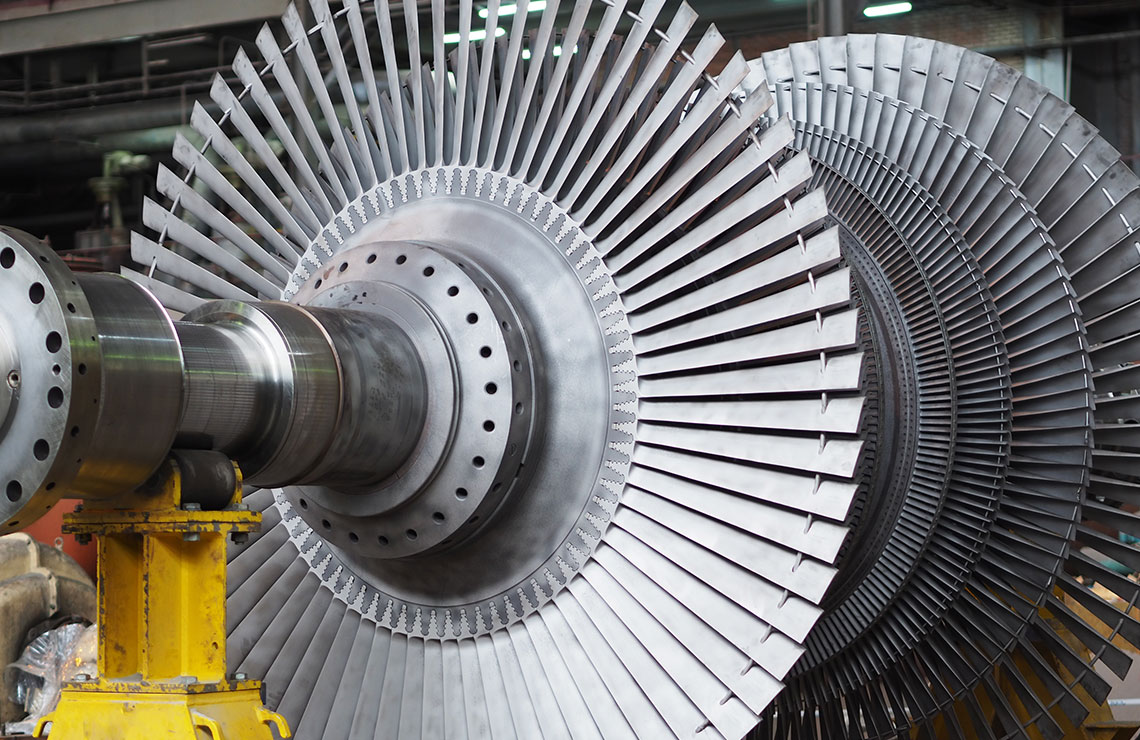

Rotating equipment introduces inherent hazards due to moving parts, stored energy, and high operating speeds. Shafts, couplings, bearings, and impellers operate under constant stress. When components degrade, the risk of sudden failure increases.

Plant safety depends on maintaining control over these risks. A bearing failure can lead to shaft seizure. A misaligned coupling can create excessive vibration. A pump operating outside its design range can overheat or rupture. Each of these scenarios poses a safety hazard to personnel and surrounding equipment.

Our rotating equipment services address these risks by identifying issues early and correcting them before they escalate. This proactive approach protects both people and assets.

What Are the Safety Risks Associated with Rotating Machines?

Rotating machines present several well documented safety risks.

- Mechanical failure can result in flying debris, fluid release, or sudden loss of containment.

- High vibration levels can loosen fasteners, damage piping connections, and compromise structural supports.

- Thermal risks are also common. Friction caused by misalignment or inadequate lubrication generates heat, which can ignite flammable materials in certain environments.

- Electrical risks may arise when motors draw excessive current due to mechanical resistance.

- Noise and vibration exposure also affect worker safety. Prolonged exposure can lead to hearing damage or fatigue, increasing the likelihood of human error. Understanding these risks underscores the importance of disciplined rotating equipment services

What Are the Risks Associated with Moving Machinery?

Rotating equipment failures often occur rapidly and without warning if underlying issues are not addressed. A cracked impeller or fatigued shaft may fail catastrophically once a critical threshold is reached.

Rotating equipment services reduce these risks by maintaining mechanical integrity and ensuring that equipment operates within safe limits. They also support safer maintenance practices by identifying components that require attention before failure.

What Safety Precautions Should You Take While Working Around Rotating Equipment?

Precautions include verifying proper alignment, ensuring adequate lubrication, and monitoring vibration levels. Lockout and tagout procedures must be supported by reliable isolation points and clear equipment condition information.

Rotating equipment services provide the data and insights needed to support these precautions. When maintenance teams understand equipment condition, they can plan work more safely and avoid unexpected hazards.

What Is the Maintenance of Rotating Equipment?

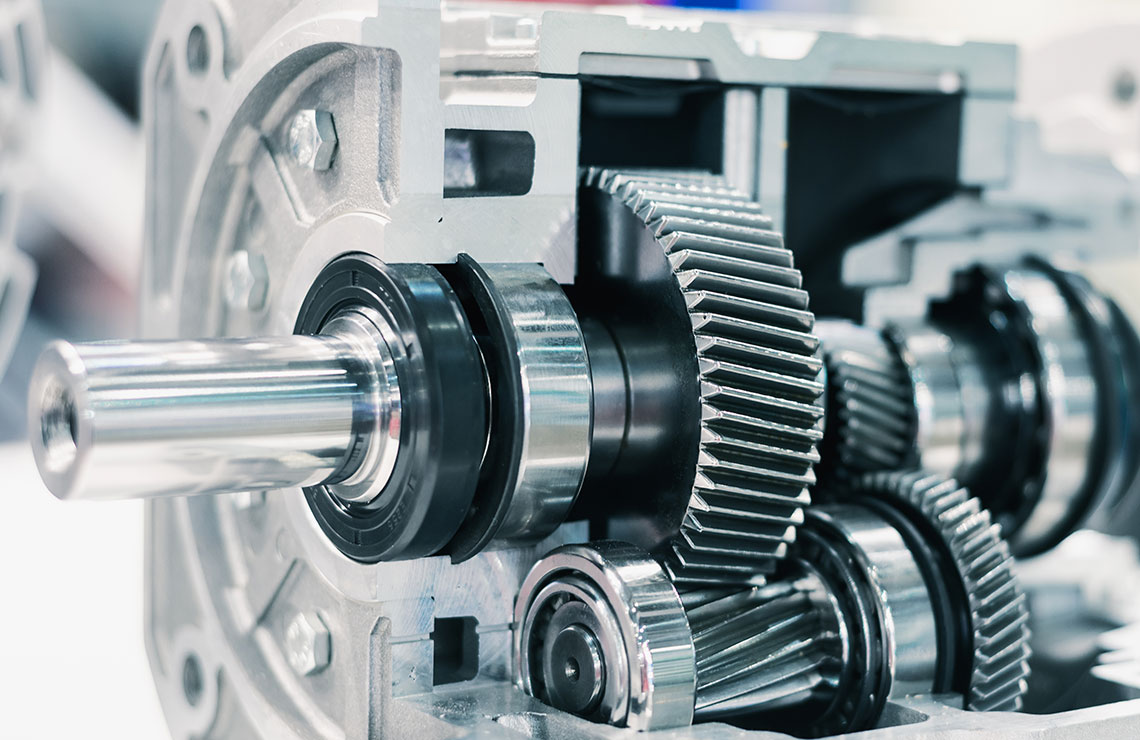

Maintenance of rotating equipment involves a combination of inspection, monitoring, adjustment, and repair. Traditional maintenance strategies often relied on fixed schedules, replacing components after a set number of hours regardless of condition.

Modern rotating equipment services focus on condition-based maintenance. Techniques such as vibration analysis, lubrication & oil analysis, PdM predictive maintenance reporting and tracking, and root cause failure analysis provide insight into actual equipment health.

This approach allows maintenance teams to address issues at the right time. Components are neither replaced too early nor left in service too long. From a safety perspective, this reduces the likelihood of unexpected failures that put personnel at risk.

How Rotating Equipment Services Improve Plant Safety

Services such as alignment verification, balancing, and vibration analysis also improve equipment stability. Stable equipment operates with less noise, less heat, and less stress on surrounding systems. This creates a safer working environment overall.

The Role of Rotating Equipment Services for Industrial Plants

For example, a pump operating inefficiently may cause upstream or downstream equipment to operate outside safe limits. Correcting the pump issue improves safety across the system.

In critical applications such as oil and gas, chemicals, and power generation, rotating equipment services help maintain compliance with safety standards and internal operating procedures. They provide documentation and data that support audits and inspections.

How Vibration and Condition Monitoring Support Safety

Abnormal vibration patterns often indicate developing faults. By responding to these signals early, teams prevent failures that could expose personnel to harm. Condition monitoring also reduces the need for intrusive inspections, limiting exposure to hazardous environments. From a safety management perspective, monitoring supports a proactive culture. Decisions are based on data rather than assumptions, reducing risk at every stage of the equipment lifecycle.

Managing Safety in Aging Rotating Equipment

Aging equipment often exhibits increased vibration, reduced efficiency, and higher maintenance demands. Rotating equipment services help identify which assets remain safe to operate and which require intervention.

This prioritization supports safer operations by focusing resources on the highest risk assets. It also informs modernization planning, aligning safety improvements with long term business objectives.

Integration of Rotating Equipment Services into Safety Programs

When rotating equipment data is shared effectively, teams can coordinate shutdowns, schedule maintenance safely, and reduce exposure to hazardous conditions. This integration strengthens safety culture and improves operational discipline.

Lifecycle Perspective on Rotating Equipment and Plant Safety

During commissioning, baseline measurements establish safe operating references. During operation, ongoing monitoring tracks deviation. During modernization, services validate improvements and confirm that new configurations operate safely. This lifecycle approach supports continuous safety improvement rather than reactive response.

Supporting Plant Safety with Proconex Rotating Equipment Services

Through condition monitoring, diagnostics, and field expertise, Proconex helps teams identify hazards early and maintain control over critical assets. Their services support safer maintenance, improved reliability, and stronger compliance across regulated environments.

Learn more about how Proconex supports safe and reliable operations by exploring our rotating equipment services at https://www.proconexdirect.com/services/rotating-equipment-services/