For plant managers, reliability engineers, and operations leaders, isolation valves are fundamental to safety, uptime, and maintainability. While they are often viewed as simple on off devices, the reality is more nuanced. Selecting the wrong isolation valve, or applying the right valve incorrectly, can introduce risk, extend downtime, or complicate maintenance activities.

Understanding isolation valves, their differences, and best practices is essential for reliable industrial operations.

What Is an Isolation Valve?

An isolation valve is a mechanical device used to stop or allow flow in a piping system. Its primary purpose is to isolate a section of the system so that maintenance, inspection, or replacement can occur without affecting the rest of the process.

Unlike control valves, which modulate flow continuously, isolation valves are typically designed for full open or full closed operation. They are used to create safe boundaries within a system, protecting personnel and equipment during planned or unplanned work.

In regulated environments, isolation valves play a direct role in safety procedures, lockout and tagout practices, and compliance with operational standards. Their reliability is not optional. It is a requirement.

What Is the Use of an Isolation Valve in Industrial Systems?

The use of an isolation valve extends beyond basic shutoff. In practice, isolation valves support several critical operational functions.

- They enable maintenance without shutting down entire units or facilities.

- They protect downstream equipment from exposure during abnormal conditions.

- They allow systems to be segmented for testing, cleaning, or commissioning.

From an operations standpoint, isolation valves reduce downtime by making systems more maintainable. From a safety standpoint, they reduce risk by providing clear and reliable separation between energized and non-energized sections of the process.

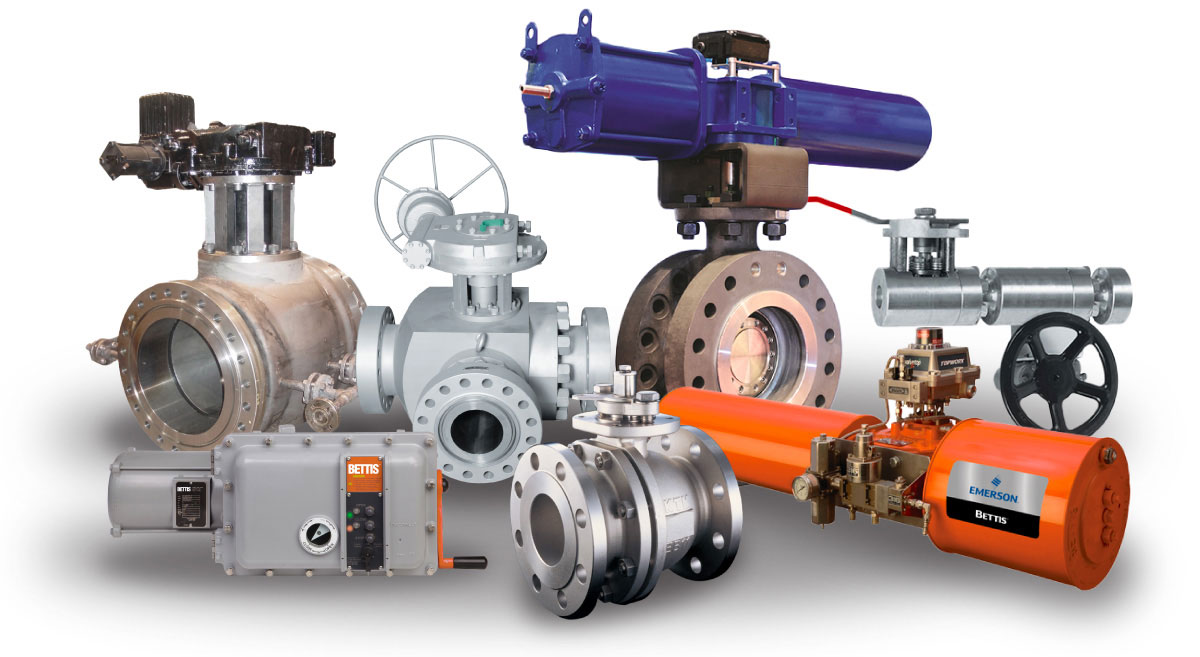

What Are the Different Types of Isolation Valves?

Gate Valves

Gate valves are commonly used for isolation in large diameter pipelines. They provide minimal flow restriction when fully open, making them suitable for applications where pressure drop must be minimized. However, they are not ideal for frequent operation and should not be used for throttling.Ball Valves

Ball valves are widely used isolating valves due to their simple operation and tight shutoff. They are well suited for applications requiring quick operation and reliable sealing. Ball valves perform best in clean services and are commonly used in utilities and process lines.Butterfly Valves

Butterfly valves offer compact design and cost effectiveness, especially in larger pipe sizes. They are often used in water, air, and utility services. While they can provide isolation, their sealing performance depends heavily on design and application.Plug Valves

Plug valves provide effective isolation and are often used in services with higher solids content or where tight shutoff is required. Their robust construction makes them suitable for demanding applications, though they may require higher operating torque.Each valve type has strengths and limitations. The best choice depends on process conditions, operating frequency, and maintenance considerations.

What Is the Best Type of Valve for Isolation?

For high pressure or critical services requiring tight shutoff, ball valves are often preferred. For large diameter, low pressure systems where cost and space are considerations, butterfly valves may be appropriate. Gate valves are commonly selected where full bore flow is required and operation is infrequent.

Selecting the best valve requires evaluating pressure, temperature, fluid properties, operating frequency, and safety requirements. It also requires understanding how the valve will be accessed and maintained over time.

How Do I Choose the Right Isolation Valve?

Choosing the right isolating valve begins with understanding the process. Key factors to consider include:

- Process media and compatibility with valve materials

- Operating pressure and temperature ranges

- Required shutoff performance

- Frequency of operation

- Installation orientation and space constraints

- Maintenance and accessibility requirements

In regulated industries, compliance considerations also play a role. Valves used in safety critical applications must meet specific standards and documentation requirements. Selecting a valve without considering these factors can create long term risk.

Reliability engineers often benefit from standardizing isolation valve types where possible. Standardization simplifies spare parts management, training, and maintenance procedures.

What Are Common Problems with Isolation Valves?

Improper use is another frequent cause of failure. Using isolation valves for throttling, operating them partially open for extended periods, or cycling them more frequently than intended accelerates wear.

Environmental conditions such as vibration, temperature cycling, and exposure to corrosive substances also affect valve performance. Recognizing these factors helps teams address root causes rather than repeatedly replacing valves without solving underlying issues.

Best Practices for Using Isolation Valves

Isolation valves should be operated fully open or fully closed unless specifically designed for throttling. They should be exercised periodically to prevent sticking and buildup. Visual indicators should be used where possible to confirm valve position.

During maintenance planning, isolation valves should be included in inspections. Seals, actuators, and operators should be evaluated as part of routine reliability programs.

Documentation is also critical. Clear identification of isolation points supports safe work practices and reduces the risk of errors during maintenance or emergency situations.

Supporting Isolation Valve Selection with Proconex

By combining technical expertise with practical field experience, Proconex helps teams avoid common pitfalls and implement solutions that support safe, efficient operations. Isolation valves are critical to safety, maintainability, and operational efficiency. Choosing the right valve and applying it correctly reduces risk and supports long term reliability.

Learn more about available options by exploring our isolation valve solutions!