In your industrial flow operations, precision and uptime drive success. You need tools that deliver accurate, real-time data to keep processes humming and avoid costly disruptions.

Flexim flow meters; with their cutting-edge ultrasonic technology; are game changers for monitoring flow in liquids, gases, and steam. At Proconex, we supply these industry-leading solutions to optimize your plant’s performance. Discover why Emerson’s Flexim ultrasonic flow meters are essential for your real-time monitoring needs.

The Power of Real-Time Monitoring

Real-time monitoring lets you spot issues; leaks, blockages, or inefficiencies; before they escalate. Without it, you’re flying blind, risking downtime or energy waste. Flexim flow meters provide instant, precise flow data, empowering you to make smart decisions fast. The MarketsandMarkets report projects the ultrasonic flow meter market to hit $2.5 billion by 2028, growing 6 percent yearly. Why? Industries like yours demand reliable, non-invasive monitoring solutions.

Poor flow monitoring hurts. A Plant Engineering study ties inaccurate meters to 25 percent of process inefficiencies. Flexim clamp-on flow meters; backed by Emerson; deliver ±1 percent accuracy for liquids, slashing those risks. You stay ahead, with data you can trust.

Why Flexim Meters Stand Out

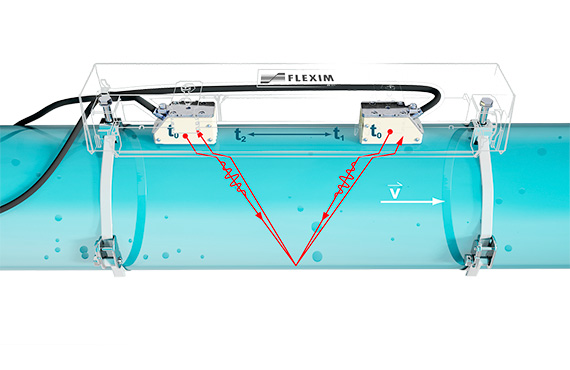

Flexim technology shines for its non-invasive, versatile design. Unlike traditional meters, Flexim’s clamp-on ultrasonic flow meters attach to the pipe’s exterior; no cutting, no downtime. Here’s why they’re essential:

- Pinpoint Accuracy: Flexim meters hit ±0.3 percent system accuracy for liquids, per Flexim. Even low flows (0.01 m/s) register perfectly.

- No Downtime: Install without shutting down; saving you hours. Clamp-on setups cut installation costs by 30 percent.

- Versatility: Handle pipes from 0.24 to 256 inches, liquids to gases, -200°C to 630°C.

- Low Maintenance: No moving parts means no wear. Flexim meters need no recalibration, saving 20 percent on upkeep.

- Hazard-Ready: ATEX and FM-certified for explosive areas, ensuring safety in refineries or chemical plants.

A chemical plant using Flexim’s FLUXUS F721 slashed downtime by 40 percent by catching a flow anomaly early. That’s real-time monitoring saving real dollars.

Key Applications for Flexim Flow Meters

Your industries rely on Flexim’s precision:

- Oil and Gas: Flexim ultrasonic flow meters monitor gas pipelines, preventing leaks.

- Chemical Manufacturing: Track corrosive fluids with zero risk of spills. A client cut waste by 15 percent.

- Power Generation: Measure steam flow up to 180°C, boosting turbine efficiency.

- Water and Wastewater: Non-invasive design ensures clean monitoring, vital for compliance.

- HVAC: Optimize cooling water flows, saving 20 percent on energy.

A power plant installed Flexim clamp-on flow meters and avoided a $50,000 shutdown by spotting a steam flow issue instantly. That’s the Flexim difference; accuracy when it counts.

How Flexim Boosts Efficiency

Efficiency is your edge. Flexim flow meters trim waste and maximize output. Real-time data flags inefficiencies fast, cutting downtime by 20 percent. Condition-based maintenance; powered by Flexim’s diagnostics; saves 25 percent on repair costs. Energy savings? Facilities see 15–20 percent power reductions with optimized flows.

Flexim’s FLUXUS G721; for instance; excels in ultrasonic gas flow measurement. Its dual-channel tech handles steam or compressed air with ease, and data logging lets you track trends. A refinery client used it to balance nitrogen flows, cutting energy use by 18 percent. Proconex delivers these wins, pairing Flexim technology with our 75 years of expertise.

Safety and Reliability with Flexim

Safety matters as much as efficiency. Flexim’s non-invasive design eliminates leak risks; no pipe cuts, no exposure. A Safety+Health Magazine report notes clamp-on meters reduce safety incidents by 25 percent in hazardous settings. Certified for Zone 1 and FM Class I, Div. 1, Flexim meters thrive in explosive environments like refineries.

A sulfuric acid plant praised Flexim’s PIOX S for non-invasive concentration monitoring. No leaks, no downtime; production rose 12 percent. You get reliability and peace of mind, backed by Proconex’s support.

Why Proconex and Flexim?

Proconex; the Mid-Atlantic’s Emerson Impact Partner; brings 75 years of know-how to your plant. We stock Flexim flow meters; FLUXUS F721, G721, and more; for industries like:

- Chemical

- Oil and gas

- Power

- Water

- Life sciences

Our 200+ pros don’t just supply; we solve. Need a flow meter for a tricky gas line? We’ll spec it. Monitoring wastewater? We’ll set you up. Flexim has been ranked at 98 percent reliability; Proconex ensures you get that standard.

Keep Your Plant Ahead

Flexim flow meters deliver the real-time data you need to stay efficient, safe, and profitable. Their non-invasive, precise technology transforms how you monitor flows, from liquids to steam. Proconex pairs Flexim’s innovation with our expertise to optimize your operations. Ready to elevate your monitoring? Visit proconexdirect.com to explore Flexim solutions tailored for you.

Frequently Asked Questions

Oil and gas, chemical, power, water, HVAC, and more rely on their precision and safety.

No. Their no-moving-parts design skips recalibration, saving 20 percent on costs.