Why Accurate Temperature Sensors Are Critical for Safety and Efficiency

The Role of Temperature Sensors in Industrial Settings

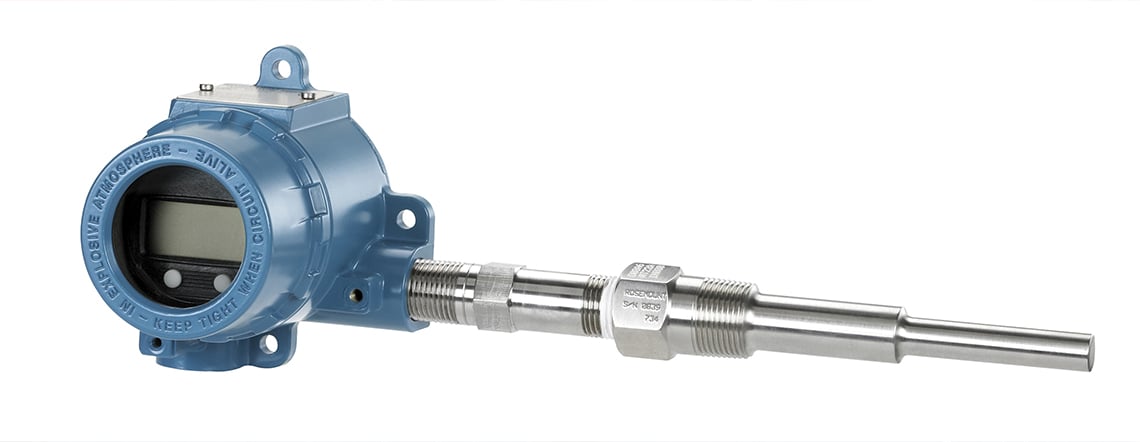

Temperature sensors measure thermal energy and translate it into readable data. In process automation, they guide control systems that regulate heat-sensitive equipment. These include thermocouples, RTDs (resistance temperature detectors), and thermistors, each suited to different applications. From maintaining consistent reaction conditions in chemical plants to monitoring pipeline temperatures in refineries, sensors provide the feedback loops that keep everything running smoothly.

Safety Starts with Accuracy

Faulty temperature readings can lead to dangerous outcomes. If a boiler runs too hot, for instance, it risks explosion. If it runs too cold, it fails to sterilize or generate steam properly. Precision in sensor readings ensures safety protocols can activate at the right moment. This is especially critical in industries where combustible materials, high pressures, or toxic substances are involved.

Explore Our Temperature Sensors

Improving Energy Efficiency

Temperature sensors are key players in energy conservation. By providing real-time data to control systems, they help optimize heating and cooling cycles, reduce standby losses, and prevent overheating. The result: lower energy bills and a smaller carbon footprint. In HVAC systems, precision sensors ensure that temperature zones are balanced without excessive cycling, boosting operational efficiency.

Preventing Costly Downtime

Enhancing Product Quality

Many manufacturing processes rely on specific temperature ranges to ensure consistent quality. In the food and beverage industry, improper temperatures can compromise safety and flavor. In pharmaceuticals, stability testing and mixing require tight thermal control. Sensors that deliver precise measurements protect product integrity and reduce waste.

Types of Temperature Sensors and Their Applications

- Thermocouples: Fast-response and durable, ideal for high-temperature or rapidly changing environments.

- RTDs (Resistance Temperature Detectors): Known for high accuracy and repeatability, often used in laboratory and cleanroom settings.

- Thermistors: Highly sensitive within narrow temperature bands, great for electronics and medical equipment.

Selecting the right sensor type depends on your process, temperature range, required accuracy, and environmental conditions.

Common Challenges and How to Avoid Them

- Sensor Drift: Over time, sensors can lose accuracy. Regular calibration and choosing robust designs help mitigate this.

- Improper Placement: A sensor must be installed where it can capture the most representative temperature, not near heat sinks or insulation voids.

- Electrical Interference: Poor wiring and external noise can distort readings. Shielded cables and proper grounding solve most issues.

Integration with Digital Control Systems

Compliance and Regulatory Requirements

When to Replace or Upgrade Sensors

If your current sensors:

- Exhibit frequent calibration drift

- Cannot withstand current process conditions

- Lack digital integration

- Are incompatible with new equipment

Future Trends in Temperature Sensing Technology

The future of temperature sensors lies in smarter, faster, and more connected solutions. Emerging designs are integrating IoT connectivity, self-calibration features, and edge computing capabilities that allow sensors to process data locally before transmitting it to central systems. This shift reduces latency and enhances response times in safety-critical applications.

Advances in nanomaterials are also improving sensitivity and durability, enabling sensors to perform reliably in extreme environments. As industries continue to embrace automation and predictive maintenance, intelligent temperature sensing will play a vital role in shaping safer, more energy-efficient facilities across every sector.

How to Choose the Right Sensor Partner

Partnering with a provider who understands your application is critical. Look for a vendor who offers not just a catalog of sensors, but engineering support, customization options, and integration expertise. A knowledgeable partner will help you avoid costly mismatches and deliver long-term ROI.

The Bottom Line

Accurate temperature sensors are a foundational element in modern industrial control. They safeguard people, enhance product quality, conserve energy, and keep your operation running efficiently. From batch production to continuous flow systems, selecting the right temperature sensors is a decision with wide-reaching consequences.

Discover Our Temperature Sensors