Introduction to Rupture Discs

According to the U.S. Chemical Safety and Hazard Investigation Board (CSB), pressure relief system failures have contributed to numerous industrial incidents. One high-profile example is the 2005 BP Texas City refinery explosion, where overpressure caused a vapor release that ignited; resulting in 15 deaths and over 170 injuries.

While pressure relief valves are essential safeguards, rupture discs offer a critical, often overlooked, layer of protection; especially in systems where leak-tight performance, rapid response, or compatibility with aggressive media is required.

Let’s explore what rupture discs are, how they work, and what you need to consider when selecting one.

What Is a Rupture Disc?

A rupture disc is a non-reclosing, single use pressure relief device designed to burst at a specific pressure level. Unlike spring-loaded valves that open and close repeatedly, rupture discs (also called bursting discs) provide instantaneous relief by rupturing in response to overpressure or vacuum conditions. They are often used in tandem with pressure relief valves or as standalone protection in systems requiring fail-safe operation with no leakage.

Rupture discs are engineered to be highly accurate and responsive to even slight variations in pressure. Most are laser- or precision-scored to ensure predictable rupture, and they come in a variety of materials, including stainless steel, graphite, and exotic alloys, to suit a wide range of media and environmental conditions.

At Proconex, we carry rupture disks from Fike’s brand of products. Learn about our Fike rupture discs and how they can enhance your safety strategy.

For deeper technical insights, see:

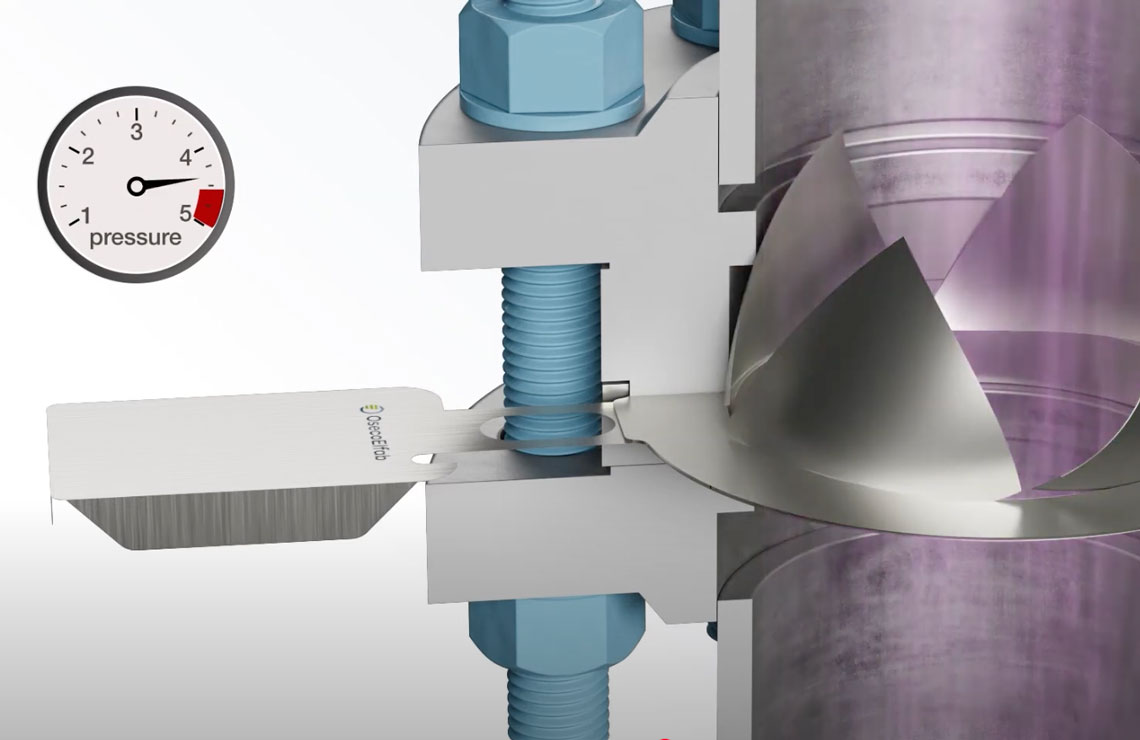

How Does a Rupture Disc Work?

Rupture discs function by responding to a predefined pressure threshold. When that threshold is exceeded; either due to system malfunction or an unforeseen surge, the disc ruptures, creating an immediate pressure relief path. This protects equipment, personnel, and production integrity.

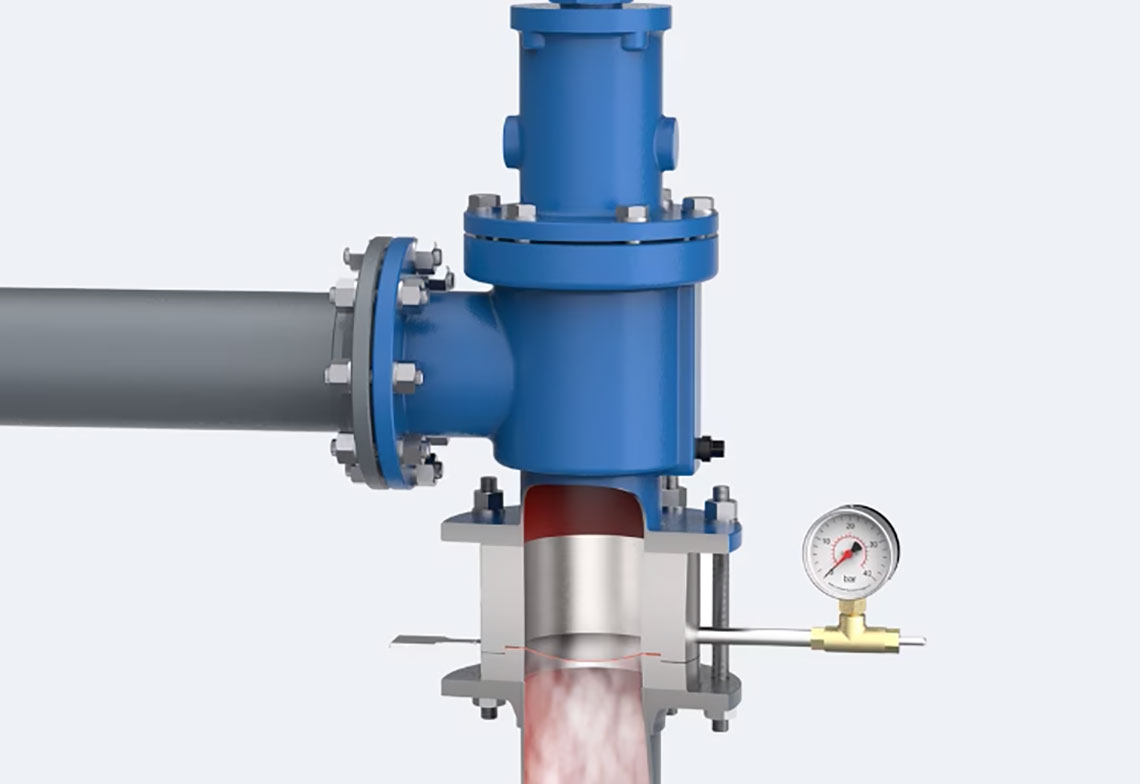

Designs vary, but a typical Fike rupture disc is precision-engineered using scored metal or composite layers to ensure predictable bursting behavior. These discs can operate alone or be paired with a rupture disc pressure relief valve system to achieve dual protection. In some industries, rupture discs are called “bursting discs” and serve vital roles in high-purity or hazardous gas environments.

In addition to safety, rupture discs also enhance system performance. They eliminate the need for complex valve assemblies in some applications, reduce the risk of fugitive emissions, and simplify compliance with industry standards like ASME and API.

Watch a rupture disc in action:

Benefits of Using Rupture Discs

- Zero leak paths: Ideal for toxic, flammable, or sterile media.

- Fast response time: Instantaneous action can prevent cascading failures.

- Corrosion resistance: Available in a wide range of materials for compatibility with aggressive chemicals.

- Cost-effective: Especially when used to protect more expensive relief valves from corrosive or dirty gases.

For high-performance applications, the Fike rupture disc is a popular choice. It's featured in our recent blog on overpressure protection for natural gas.

These discs are also useful in applications where operating conditions fluctuate or where traditional valves struggle to reseat properly. Because they are passive and do not rely on mechanical movement, they offer unmatched reliability in mission-critical systems.

External resources:

Watch the video below to see a rupture disc animation.

Choosing the Right Rupture Disc

Not all rupture discs are created equal. When selecting one, consider:

- Operating pressure and temperature

- Media compatibility

- Burst pressure accuracy

- Installation orientation

- Cycle frequency

At Proconex, we help engineers and plant managers choose the right rupture discs for their environment and process. Our expertise extends to sizing, material selection, and integration into safety systems.

We also offer on-site evaluation and troubleshooting to ensure optimal performance of your rupture disc installations. Our team supports everything from initial specification to preventive maintenance planning.

Explore the Fike rupture disc line or review our insights on natural gas system protection.

For more in-depth details, see:

Rupture Disc vs. Pressure Relief Valve: What’s the Difference?

Both rupture discs and pressure relief valves (PRVs) serve as pressure safety mechanisms; but they operate differently.

- Rupture discs are passive devices that burst once; they cannot reseal or close.

- PRVs open and close as pressure fluctuates, allowing for continuous modulation.

- Instantaneous relief

- Minimal maintenance

- Total isolation before failure

They are also frequently used upstream of PRVs to protect them from corrosive or particulate-heavy fluids; improving lifespan and reducing maintenance.

In addition, rupture discs can serve as a tamper-evident seal. In pharmaceutical and food industries, this traceability and compliance feature adds a layer of safety verification not possible with valves alone.

Compare solutions by browsing our pressure relief product line and our post on PRVs vs. safety valves.

Additional reading:

In Conclusion

Rupture discs are simple but essential components in pressure relief systems. They help prevent catastrophic failures, improve system uptime, and maintain compliance with safety standards across industries; from chemical processing and pharmaceuticals to energy and manufacturing.

Whether you're upgrading legacy systems or designing new builds, incorporating rupture discs can drastically improve safety and performance. Partnering with an expert like Proconex ensures you choose the right device for your system's needs.