In industrial plants, efficiency, safety, and uptime are everything. You rely on systems to run smoothly, delivering consistent output without hiccups.

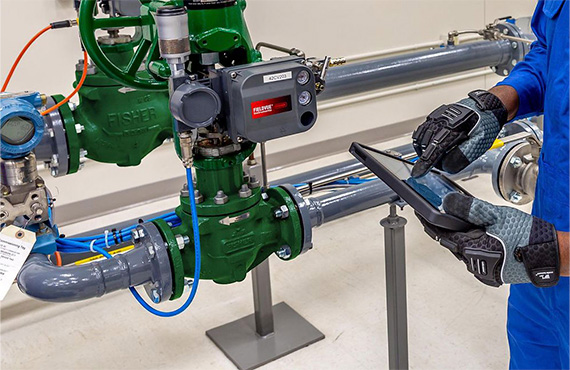

Industrial valves; whether control, isolation, or safety relief; are the backbone of that performance. These unsung heroes regulate flow, manage pressure, and protect equipment, ensuring your plant hums along. At Proconex, we supply top-tier industrial valve solutions, including trusted brands like Emerson, to keep your operations at peak performance. Explore why industrial valves matter and how they drive your success.

Why Industrial Control Valves Are Critical

Industrial valves control the flow of liquids, gases, and slurries in your plant. From steam in power generation to chemicals in manufacturing, they ensure precision and safety. Without reliable valves, you risk leaks, pressure spikes, or downtime; each a costly hit to your bottom line. The Grand View Research report pegs the industrial valve market at $85.7 billion by 2028, growing 4.2 percent yearly. Why? Demand for efficient, safe systems fuels adoption across industries like yours.

Poor valve performance drags you down. Faulty valves can cause 30 percent of unplanned shutdowns. Conversely, high-quality industrial control valves slash maintenance costs by 25 percent, per Processing Magazine. Investing in robust valve solutions; like those Proconex offers; keeps your plant competitive and resilient.

Key Roles of Industrial Valves

Industrial valves do more than open and close. They optimize your plant in critical ways:

- Regulate Flow: Industrial control valves fine-tune flow rates, ensuring processes like chemical dosing or steam delivery stay precise.

- Ensure Safety: Safety relief valves, like Emerson’s Crosby line, release excess pressure, preventing catastrophic failures.

- Boost Efficiency: Properly sized valves reduce energy waste; think 15–20 percent power savings.

- Protect Equipment: Isolation valves stop flow to safeguard pumps or reactors during maintenance, cutting repair costs.

- Minimize Downtime: Reliable valves prevent leaks or clogs, boosting uptime by 20 percent.

A Gulf Coast refinery swapped outdated valves for Emerson’s Anderson Greenwood models. Result? Downtime dropped 35 percent, and safety incidents fell to zero. That’s the power of smart industrial valve applications.

Types of Industrial Valves

You need the right valve for the job. Different types suit specific needs:

- Control Valves: Adjust flow, pressure, or temperature; ideal for chemical plants or HVAC systems.

- Safety Relief Valves: Release overpressure to protect boilers or pipelines. Crosby valves lead in reliability.

- Isolation Valves: Shut off flow for maintenance; think gate or ball valves in oil and gas.

- Check Valves: Prevent backflow, safeguarding pumps in water systems.

Each type tackles unique challenges. Control valves dominate 40 percent of industrial applications for their precision. Proconex helps you pick the perfect fit, ensuring optimal performance.

Real-World Impact of Industrial Valve Solutions

Industrial valves shine across your industries:

- Chemical Manufacturing: Control valves regulate corrosive fluids, preventing spills.

- Oil and Gas: Safety relief valves protect pipelines from overpressure.

- Power Generation: Isolation valves enable safe turbine maintenance, boosting uptime.

- Life Sciences: Sanitary valves ensure sterile processes, critical for pharmaceuticals.

A power plant using Proconex-supplied Crosby valves avoided a $100,000 shutdown by catching a pressure spike early. That’s industrial valve importance in action; real savings, real results.

How Valves Optimize Efficiency

Efficiency drives your profits. Industrial valves trim waste and maximize output. Precise control valves optimize flow, slashing energy use by 15 percent, per Hydrocarbon Processing. Safety valves prevent costly blowouts; think $50,000 saved per incident. Regular maintenance, paired with quality valves, cuts downtime by 25 percent, says Modern Pumping Today.

Take a chemical plant. They upgraded to Anderson Greenwood control valves, guided by Proconex. Energy costs fell 20 percent, and maintenance dropped 30 percent. Data-driven valve selection, backed by Emerson’s tech, makes these wins repeatable. You get tighter control, lower bills, and a stronger bottom line.

Why Choose Proconex for Industrial Valves?

Proconex brings 75+ years of expertise as the Mid-Atlantic’s Emerson Impact Partner. We stock a full range of industrial valves; Crosby, Anderson Greenwood, and more; ready for your plant. Our 300+ pros serve industries like yours:

- Chemical

- Oil and gas

- Power

- Life sciences

- Refining

We don’t just supply valves; we solve problems. Need industrial control valves for a reactor? We’ll spec and install them. Facing overpressure risks? Our safety valves have you covered.

Your Path to Peak Performance

Industrial valves are your plant’s pulse, keeping processes safe, efficient, and reliable. From regulating flow to preventing disasters, they’re critical for staying ahead. Proconex offers tailored industrial valve solutions, backed by Emerson’s innovation and our decades of know-how. Ready to optimize your plant? Connect with us to explore how our valves can elevate your performance.

Frequently Asked Questions

They release excess pressure to prevent equipment damage or explosions, protecting systems like boilers or pipelines.

Chemical, oil and gas, power, life sciences, refining, and more rely on valves for safe, efficient operations.