Your industrial plant thrives on uptime and efficiency. A single equipment failure can halt production, rack up repair costs, and disrupt your entire operation.

Wireless condition monitoring changes the game by keeping tabs on your equipment’s health in real time, spotting issues before they spiral. At Proconex, we bring you top-notch wireless solutions from Emerson to fine-tune your process control. Let’s dive into what these devices do, why your facility needs them, and how our wireless condition monitoring products can keep your plant running like a well-oiled machine.

What Is a Wireless Condition Monitor?

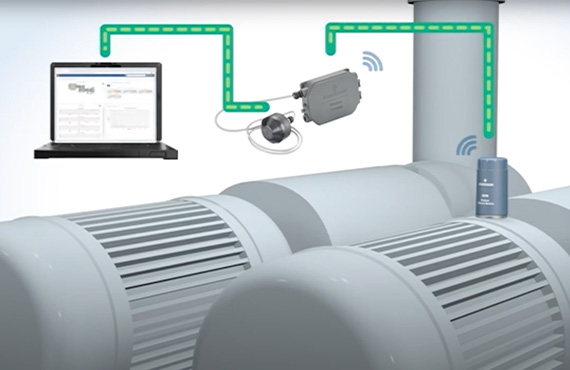

Imagine a small, rugged sensor that watches your equipment like a hawk, tracking things like vibration, temperature, or pressure without a single wire. That’s a wireless condition monitor. It bolts onto your pumps, motors, or turbines, sending live data to your control room to flag problems—think bearing wear or overheating—before they shut you down. Unlike clunky wired systems, these sensors go up fast, even in hard-to-reach spots like high-up compressors or remote pipelines.

These devices lean on tech like ultrasonic sensors or infrared to catch tiny changes in equipment behavior. They talk to your system via secure wireless networks, giving you a constant stream of insights. No need to tear apart your setup or halt production to install them. That flexibility, paired with pinpoint accuracy, makes them a cornerstone for staying ahead of plant breakdowns.

Why Does an Industrial Facility Need Wireless Condition Monitors?

Your plant’s equipment works overtime—pumps churning, motors humming, compressors grinding. But wear-and-tear sneaks up. A loose bearing or a hot motor can snowball into a full-blown failure if you don’t catch it early. Wireless condition monitoring gives you eyes on every critical piece, helping you stay proactive. Here’s why they’re a must-have:

- Head Off Failures: Catch issues like misalignment before they stop your line.

- Trim Repair Bills: Predictive maintenance saves 20 percent on fixes.

- Keep Workers Safe: Monitor risky areas—like chemical reactors—without sending techs into harm’s way.

- Save Power: Fine-tuned equipment burns 15 percent less energy.

Without these monitors, you’re stuck reacting to problems after they hit, bleeding time and money. With them, you shift to predicting and preventing, which keeps your plant lean and competitive.

Take a chemical plant, for example. Motors driving mixers are tough to check manually; too high, too hot, too risky. Wireless sensors can sit on those motors, sending vibration data to spot trouble early. That kind of foresight stops a $10,000 repair job before it starts. Or picture a power plant with steam turbines. Temperature spikes can mean big trouble, but wireless monitors catch them instantly, keeping things humming. These aren’t just gadgets; they’re your edge in a high-stakes game.

Wireless Condition Monitoring Solutions from Proconex

Proconex has been solving plant problems for over 75 years. We don’t just sell wireless condition monitoring devices; we tailor it to your needs. Our lineup of Emerson products is built to handle your toughest challenges:

- Emerson AMS 9420 Vibration Transmitter: Slaps onto pumps or fans to track vibration; its wireless setup means you’re up and running in hours.

- AMS Wireless Temperature Transmitter: Keeps an eye on motor or turbine heat; tough enough for corrosive or explosive zones.

- Plantweb Insight: Crunches data from all your sensors; sends clear alerts so you can act before a breakdown hits.

Our team works with industries like chemical, oil and gas, power, life sciences, and refining, building solutions that fit your plant like a glove. Need monitors for a noisy compressor in a refinery? We’ll spec the AMS 9420 and get it humming. Got a water treatment facility with spread-out pumps? Our temperature transmitters have you covered.

We’ve seen plants transform with these tools. A Processing Magazine article highlights how wireless monitoring can shave maintenance budgets by catching issues early. That’s not just theory; it’s what we deliver. Our clients in power generation, for instance, use Plantweb Insight to spot turbine imbalances before they cause outages, saving hours of lost production. In chemical plants, our vibration transmitters flag pump issues, cutting repair costs and keeping hazardous processes safe.

Why Go Wireless?

Wired systems are a hassle; cables snag, corrode, or just can’t reach remote gear. Wireless condition monitors ditch those headaches. You install them without ripping up your plant or pausing operations. They’re tough, too, built for dusty refineries, steamy power plants, or sterile pharma labs. Plus, they scale easy; add more sensors as your needs grow, no overhaul required.

Safety’s another win. Sending techs to check equipment in hazardous zones is risky and slow. Wireless monitors do the job remotely, keeping your team out of danger. They’re certified for explosive areas—ATEX and FM Class I, Div. 1—so you’re covered in places like oil and gas or chemical plants. Safety+Health Magazine reports wireless tech can cut safety incidents by 25 percent in high-risk settings. That’s peace of mind you can’t put a price on.

The Bigger Picture

Wireless condition monitoring isn’t just about dodging breakdowns; it’s about running your operations smarter. Real-time data lets you plan maintenance when it’s least disruptive, not when a motor blows. You optimize energy use, stretch equipment life, and keep regulators happy with consistent performance. That’s time and money back in your pocket.

Proconex doesn’t stop at handing you a sensor. We dig into your operations—your industry, your equipment, your goals—and build a solution that works. Our partnership with Emerson means you get battle-tested tech backed by our hands-on support. Whether it’s a single pump or a sprawling refinery, we’ve got the tools and know-how to keep you ahead.

Conclusion

Wireless condition monitoring is your ticket to a leaner, safer, more reliable plant. From catching vibration quirks to tracking temperature spikes, these devices give you the edge to stay proactive. Proconex combines Emerson’s rock-solid tech with our 75 years of problem-solving to deliver what your facility needs. Want to cut costs, boost uptime, and keep your team safe? Explore our wireless condition monitoring products today! Head to proconexdirect.com to see how we can help.

People Also Ask

It reduces downtime by 20 percent and costs by 20 percent; sensors like Emerson’s AMS 9420 deliver real-time data.

Use live data to predict issues; wireless monitors enable proactive fixes.