This guide explores how to select the correct butterfly valve for your process needs by evaluating key factors like flow requirements, system pressure, fluid type, and actuation preferences. Whether you’re upgrading an aging pipeline or designing a new installation, making the right selection can improve system reliability, reduce maintenance costs, and boost overall efficiency.

What Is a Butterfly Valve?

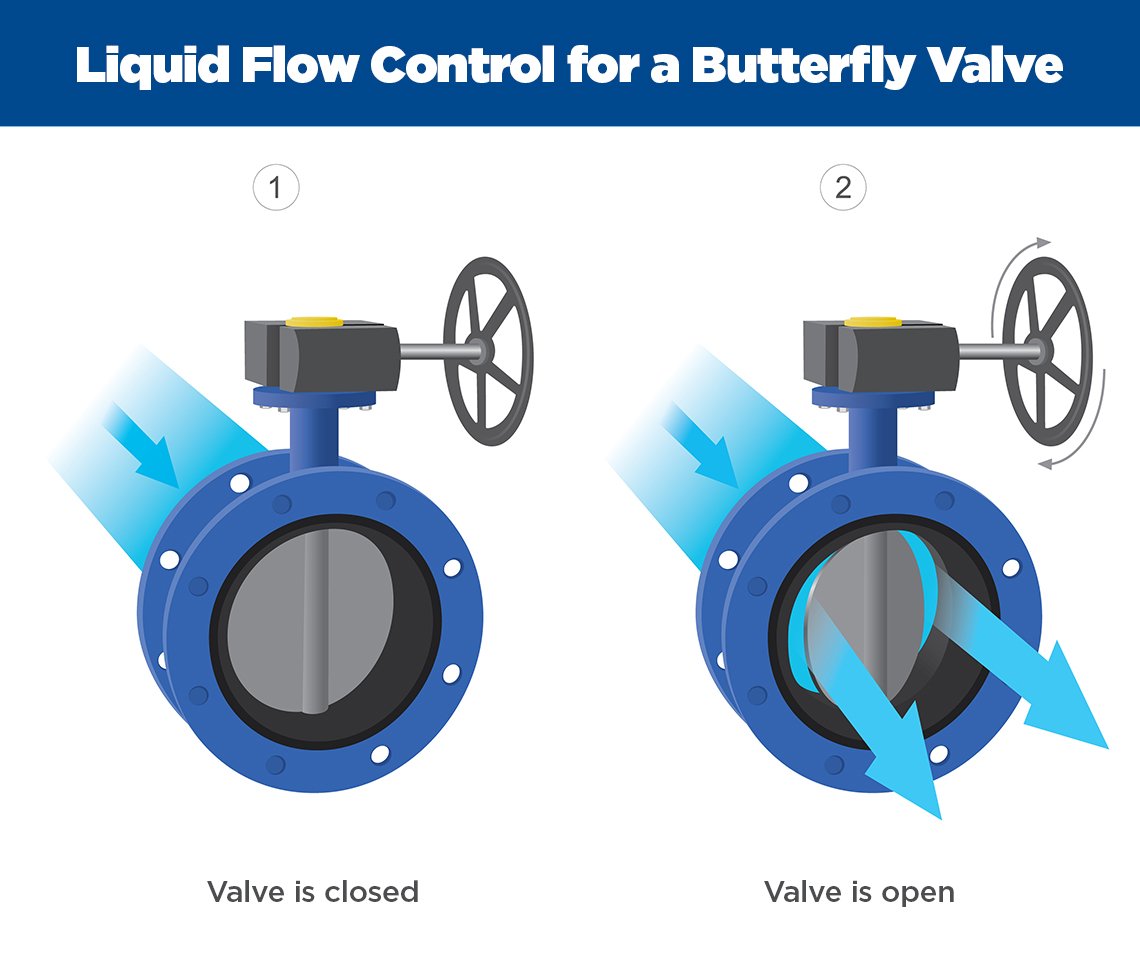

A butterfly valve is a quarter-turn flow control device used to regulate, isolate, or throttle fluid within a piping system. The main component is a rotating disc that pivots in the center of the pipe to allow, restrict, or stop flow. When the disc is parallel to the flow, the valve is open. When turned perpendicular, it blocks the passage.

Types of Butterfly Valves

- Concentric: Basic design with the stem passing through the disc's center. Suitable for low-pressure systems.

- Double Offset: Disc is offset from the centerline, reducing wear and improving sealing.

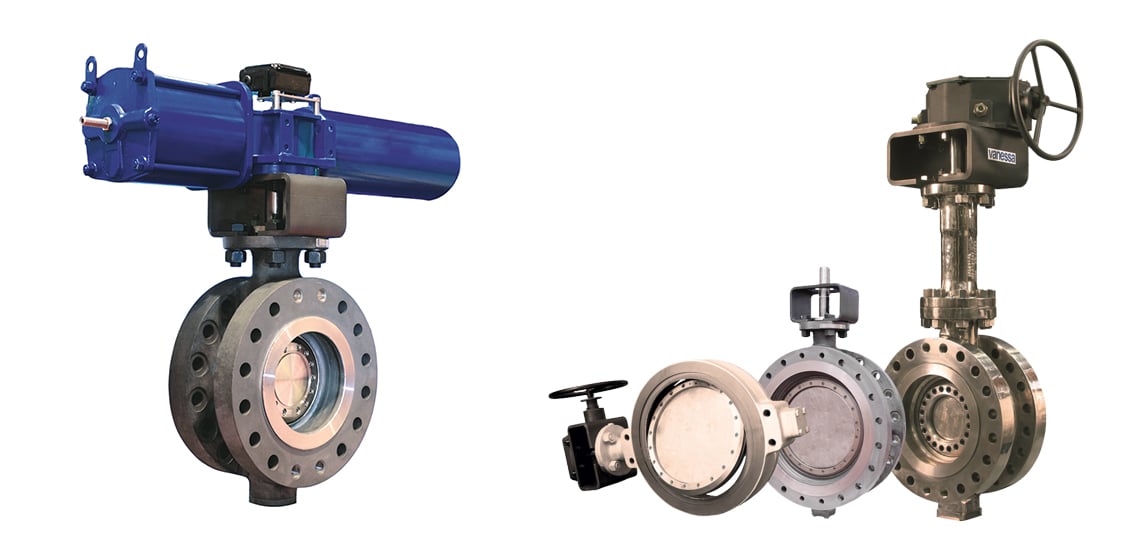

- Triple Offset: Includes a third offset for metal seating, ideal for high-temperature or high-pressure conditions.

Each valve type offers unique benefits depending on the service conditions.

When Should You Use a Butterfly Valve?

Butterfly valves are ideal when space is limited or when you need reliable, quick shut-off. Common use cases include:

- HVAC systems

- Water distribution

- Wastewater treatment

- Fire protection systems

- Chemical and food processing

Their streamlined body allows for easy installation in tight areas, and their simplicity makes them cost-effective compared to other valve types.

Flow Control Requirements

Flow rate and line size directly affect valve selection. Undersizing the valve could cause pressure drops, while oversizing may result in poor control and valve instability. Always refer to manufacturer flow coefficient (Cv) ratings to match the valve to your expected flow volume.

Fluid Type and Compatibility

- EPDM seats are great for water and air

- Viton resists oils and acids

- PTFE handles aggressive chemicals

- Stainless steel bodies provide corrosion resistance for harsh environments

Pressure and Temperature Ratings

System pressure and temperature directly impact valve design. Higher pressures require more robust construction and better sealing technologies. For instance, triple-offset valves, such as the popular Vanessa Series 30,000 Triple Offset Valves shown below, are more suitable for high-pressure steam applications compared to concentric designs.

In addition, thermal cycling can affect seal performance. Look for valves with flexible seats or fire-safe certifications if operating in high-heat environments.

Valve Actuation Options

Manual, electric, pneumatic, and hydraulic actuators are all compatible with butterfly valves. Your choice depends on control requirements, system integration, and budget.

- Manual levers are cost-effective for low-use systems

- Electric actuators allow for remote or automated operation

- Pneumatic actuators are fast and suitable for on/off service

- Hydraulic actuators provide high force for large-diameter valves

Automated systems often benefit from valves with ISO 5211 mounting pads for easy actuator integration.

Installation Environment

Consider external factors that may influence valve performance:

- Indoor vs. outdoor exposure

- Accessibility for maintenance

- Potential vibration or seismic conditions

- Clean or hazardous locations

Butterfly valves with weatherproof, explosion-proof, or corrosion-resistant coatings may be required depending on the installation environment. Evaluate mounting space and orientation early in the selection process.

Industry Standards and Certifications

Ensure the valve meets relevant industry standards such as:

- API 609 (butterfly valve design)

- ISO 9001 (quality)

- NSF 61 (potable water)

- ASME B16.1/B16.5 (flange compatibility)

Certifications demonstrate product reliability and ensure your system complies with applicable regulations. Consult your quality assurance team before finalizing the selection.

Common Butterfly Valve Mistakes to Avoid

Selecting the wrong valve can cause system failure, costly repairs, and safety risks. Avoid these common pitfalls:

- Failing to consider material compatibility

- Using a manual valve for high-cycle or remote applications

- Overlooking temperature and pressure ratings

- Ignoring maintenance accessibility

Choosing the Right Supplier

Valve performance depends on both product quality and expert guidance. Choose a supplier that offers:- Engineering support

- In-stock availability

- Application-specific recommendations

- Field services and lifecycle maintenance

Discover Our Butterfly Valves to find high-performance options for any flow control requirement. Our team helps clients navigate the complexities of valve selection through hands-on experience and industry knowledge.

Whether you’re selecting for corrosive environments, high-pressure steam, or food-grade media, we’ll help match the right butterfly valve to your needs.

To Summarize

The right butterfly valve enhances system efficiency, reduces maintenance downtime, and provides reliable control for years to come. By understanding your process conditions and operational needs, you can make an informed decision that pays off in both performance and longevity.

Proconex provides a wide selection of butterfly valves for isolation and flow control, backed by application support and technical expertise. Reach out today to streamline your valve selection process and get expert advice on fitting your specific application.

Explore Our Butterfly Valve Solutions